Zestfloor – Connected MES for Smarter Industries

Enhancing manufacturing efficiency through seamless data integration and real-time insights.

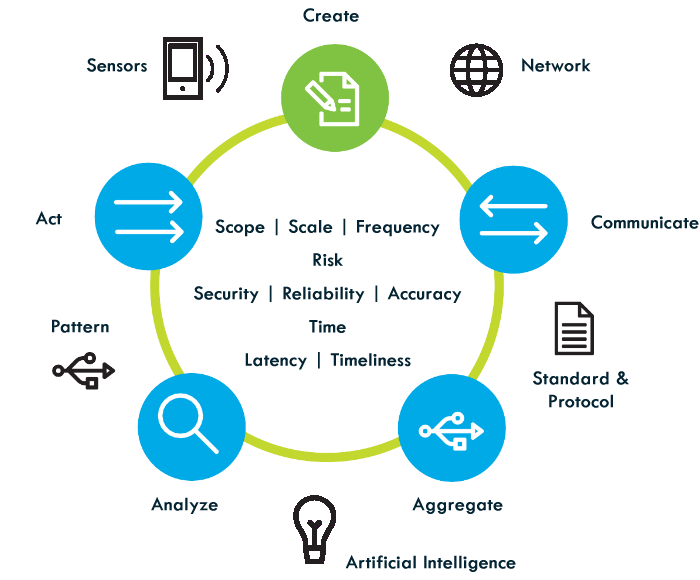

An advanced MES system seamlessly bridging the gap between operational technology (OT) and information technology (IT). It connects with all types of machines, leveraging the power of Industrial Internet of Things (IIoT) and machine learning algorithms. Zestfloor transforms your shop floor into a fully automated environment, enhancing agility and operational efficiency. Moreover, Zestfloor takes the lead in creating a digital twin—a virtual representation—of your manufacturing facility. By tracking both current and historical states, Zestfloor optimizes processes and drives continuous improvement

Request for Demo Chat with SalesZestfloor ! Manufacturing Solution supporting Physical – Digital – Physical Loop

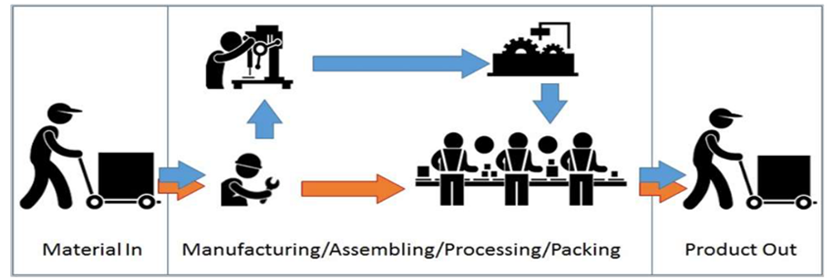

Data acquisition to Process Streamlining

Smart Factory leverages machine intelligence, connected sensors, advanced analytics, control tower capabilities, and other intelligent tools to help you address a number of potential use cases, including resource utilization:

Digitalize the Data Entry right from Material in to the respective Storage Location at each Plant. Followed by the planning to be carried out for Resourcing, Production and Capacity.

Capacity Planning

Production Planning

Resource Planning

Data Capturing is the key activity which will be automated connected to all Machines/ Equipment directly or as an extraction of file holding the real time parameters. These data helps to analyze and arrive at complex reports like CP/CPK & PP/PPK and the difference between them.

Post Production process for the accessories/ Products, physical quality check will be done before moving it to FG Warehouse.

Our Solutions can help you understand what’s possible for transforming manufacturing and take action in a meaningful way.

Whether it’s bringing predictive, intelligent capabilities to a specific product line or undertaking an end to end transformation of your entire manufacturing environment.

Zestfloor – MES for Smarter Industries

-

IoT and Machine data acquisition & system mapping

IoT and Machine data acquisition & system mapping

-

Integration across lines and other systems

Integration across lines and other systems

-

Centralised data-driven manufacturing insights.

Centralised data-driven manufacturing insights.

-

Traceability and Reliability of Information across Supply Chain.

Traceability and Reliability of Information across Supply Chain.

Smart Factory | key capabilities:

- Autonomous process control

- Total operations synchronization

- Operations command center

- Traceability

- Resource tracking and Efficiency.

- Dynamic operations sensing

Zestfloor – Business Architecture

PLAN

Production Planning

Production order, BOM, Routings, Variants, Operations, Work center, Shift Roster, Work Centre Groups.

Inventory Management

Material classification, Inventory, Reservations, Stock, Storage locations, Goods Receipt, etc.

Quality Management

Inspection lots, characteristics / attributes, Non conformance, etc.

Version Management

BOM, Recipe Changes to be captured with version effectivity

EXECUTE

Production/ Job Order

Job Card

Monitoring/ Data Capturing

Test & Re-work

Packing & Dispatch

Yield confirmation, Scrap confirmation, Rework confirmation, Goods movements, Material consumption, Resource Time booking, Quality inspection results,, Equipment usage, Tool usage.

AUTOMATION

Plant DB

Wireless Integration

Mobile Compatible

Sensors

SCADA/HMI

Automation to capture the movements, identify the Problem areas and Track the flow in Shop Floor. Paperless Solutions towards real time capturing of data.

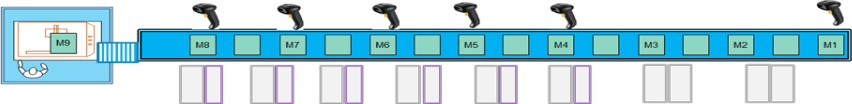

Zestfloor – Our Flagship product for EMS Industries

Track, Trace and Control

SMT Line

Assembly Line

Packaging & Dispatch

Inward Outward

Traceability, Interoperability, Real-time production monitoring, Enforcing stringent Quality processes, Cost optimization and much more!

Zestfloor – EMS version offers the manufacturers better quality monitoring through interoperability, which can be achieved in real time.

Zestfloor combined with iBWMS, Zestlink and Turbozest of our product suite gives you a 100% connected data flow and visibility right from Material inward to SMT to Assembly to Packaged and Dispatch.

With our own IP owned communication protocol, any new machine of any make or model can be connected to the rest of its ecosystem within few days as against spending several months in the past.

Effectively, we have made communications between Machine to Machine and Machine to Human to Machine real time with alerts and actions to be taken in the production process visible to the ones connected to the ecosystem.

This also helps in the Process, Product, Component, Consumables and Tool traceability.

Material identification and Tracking starts from Inward,

- Warehouse Layout (Virtual Plotting)

- Storage Sections

- Storage positioning

- Storage Type

- Dock Management

- Strategies at Storage Bins.

- Master Data Setup

- Handling Equipment

- Gate Pass

- Transport Management

SMT Line

- Inventory tracking of Components at each stage of Issue

- Kitting Control (follows the FIFO/ FEFO strategy)

- Setup Verification and Process control, FAI to all quality parameters taken into consideration.

- Solder Paste Management, Stencil and other tool management

- MSD Control

- Route Control with every stage tracked

- Rework and Repair management

- Integration Protocols with all Machine Makes including ICT, RF, Routers and other Machines.

Assembly Line

- WIP Inventory tracking at each stage giving real time inventory.

- Integrated with MI/ AI line to support the process through PTH and WSM machines for tracking including Jig verification and Strokes.

- Integration with ODM/ OEM machines/ systems to get the throughput for seamless interlock at every process

- to extract data from Bluetooth testing machines against MAC ID and IMEI and relate it to the serial number.

- Supports Auto as well as Consumer Electronic industry end to end.

Packaging Line

- Pairing to Mono box/ GB carton for complete traceability till the very last component.

- Generate labels of all sizes and requirements for Packaging.

- Integrate with Label printers and scanners.

- Detailed Quality module to capture the testing (100% sampling or Random sampling with respect to time or quantity) is supported.

- Generation of labels against GB/ Carton/ Pallets and movement to Warehouse (Dispatch) against Delivery.

Traceability (Zestfloor)

ManpowerOperator Name/ID |

MaterialMaterial tracking with Unique ID, Part Number |

Method/ProcedureProduct & Work Order |

||

|

|

|

|

|

MachineAll process records directly from machines |

Tools & ConsumablesTools used on machines |

Manpower

Operator Name/ID

Each Operation's Start & End Date/Time

Machine

All process records directly from machines

Trace from material info (e.g., lot code, reel ID) to find units produced

Material

Material tracking with Unique ID, Part Number

Supplier, Lot & Date Codes MSD Information

Tools & Consumables

Tools used on machines

Specific tools

Life Cycle Management - No.of Strokes Cleaning Process

Method/Procedure

Product & Work Order

Line Details

Machine/Workstation ID

Zestfloor – Enabling the Digital World

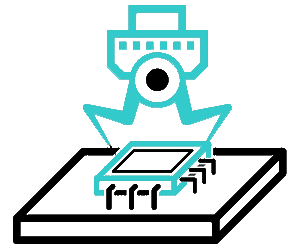

OCR

OCR enablement supports and makes life easier where the majority of companies have challenges since none of ERPs or any application captures critical data like MPN, Mfg. date and LOT number. It also saves $$ by avoid buying Machines.

Interlock

Interlocking at every possible stage right from SMT to Assembly eliminating the possibility of defect boards to move down the line. Use of PLC automation to STOP the conveyor in case of anomaly either in materials, machines or processes.

Traceability

Complete automation of traceability end to end including WIP tracking and Handling nit where the SMT or boards that are completed with processes are stocked.

Process and Part traceability Automation.

Machine Data

Ability to integrate all Model and Make of Machines in SMT, Assembly and Testing Lines. We also provide the option of having all done in our application saving you the cost of licenses but still provide all the features expected.

Zestfloor – Customer Success